Note

Access to this page requires authorization. You can try signing in or changing directories.

Access to this page requires authorization. You can try changing directories.

Important

Some of the functionality described in this release plan has not been released. Delivery timelines may change and projected functionality may not be released (see Microsoft policy). Learn more: What's new and planned

| Enabled for | Public preview | General availability |

|---|---|---|

| Users, automatically |  Apr 1, 2025

Apr 1, 2025 |

Jan 2026 |

Business value

Sustainability Scope 3 value chain process automation uses standard ERP processes to streamline how you collect, calculate, and report indirect emissions data across your company's upstream and downstream value chain. This automation improves accuracy, efficiency, and compliance with sustainability goals. Scope 3 emissions are important for accurate tracking because they make up most emissions, influence business decisions, and align with many regulations.

Scope 3 emissions are also the most complex to measure because they require data from many sources. For example, you need data from vendors and internal operations such as transfers and manufacturing. This feature gives you more control by letting you track emissions in the manufacturing process and automatically calculate new emissions in both downstream and upstream activities related to your inventory.

Feature details

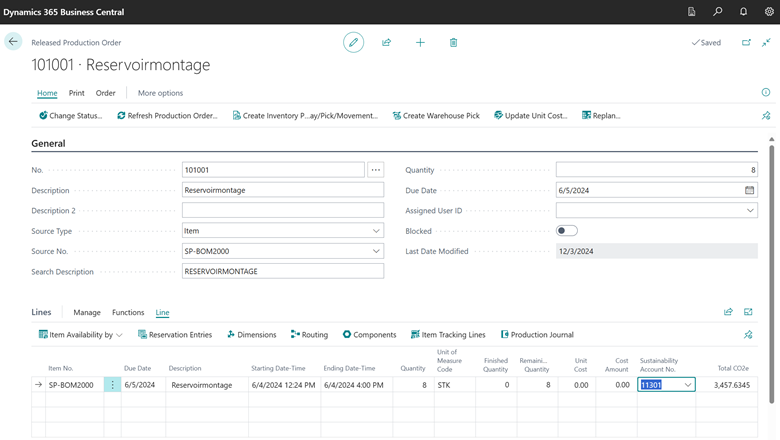

With this feature, you can calculate CO2e for finished goods by using raw material emissions data from purchase documents and adding emissions from manufacturing processes.

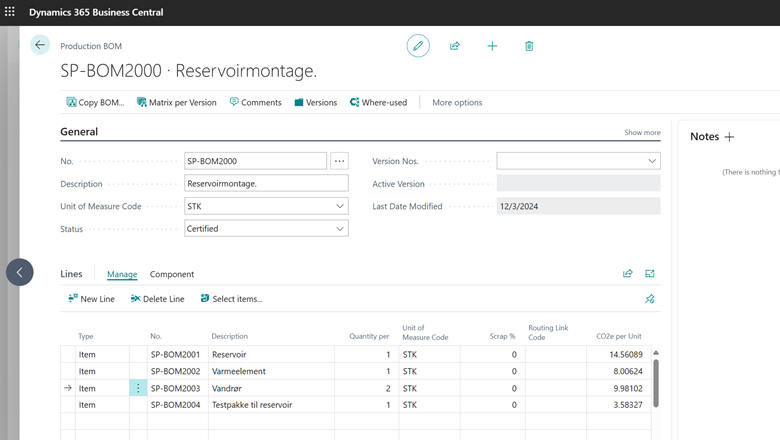

To help you collect this data, the new CO2e per Unit and Total CO2e fields are available on the following pages:

- Production BOM

- Routing

- Components

- Operations

- Production Order Lines

- Consumption

- Output Journals

On the Production BOM page, these fields get their values from the emission details of items. On the Routing page, they come from the emission details on the Work and Machine Centers pages.

The system calculates these fields by using the Average method on the Sustainability Value Entries page. When you run the Refresh Production Order action, you can see the calculated values on the production order. Each time you post, Business Central adds new values to the Sustainability Value Entry page for the finished goods. These values come from the consumption of raw materials and the output of operations.

The consumption and output entries create a Sustainability Value Entry that links to the Item Ledger Entry. The output entry also connects to the Capacity Ledger Entry. To prevent double postings for the same emissions, these entries post only to the Sustainability Value Entry and not to the Sustainability Ledger Entry. These entries relate only to the item emission valuation.

Geographic areas

Visit the Explore Feature Geography report for Microsoft Azure areas where this feature is planned or available.

Language availability

Visit the Explore Feature Language report for information on this feature's availability.

Tell us what you think

Help us improve Dynamics 365 Business Central by discussing ideas, providing suggestions, and giving feedback. Use the forum at https://aka.ms/bcideas.